No products

Prices do not include tax.

Transporting refrigerated medicines and vaccines

Transporting refrigerated medicines requires a series of very specific characteristics, which must be adjusted to both the type of medicine and the means of transport used. In this sense, understanding the essential factors that must be met for each shipment is strongly advised. The goal is to ensure that the drug maintains all its properties.

In the following sections, we expand on this information and explain why refrigeration is a key factor in achieving the best preservation of medicines and preventing their deterioration. Therefore, using thermometers or temperature indicators that are suitable to monitor the cold chain of medicines is extremely important.

Types of Transporting medicines and vaccines

- Medicine refrigerators

Preservation of thermolabile medicines

Refrigeration is needed for the conservation of thermolabile medicines. For example, vaccines, biological preparations and reagents for some clinical tests should be kept below a specific temperature. In these cases, the storage temperature for medicines requires an unbroken cold chain. Otherwise, the patients who make use of them could be put at risk.

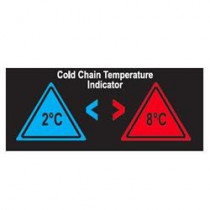

For this matter, using cold indicators and sensors is very important to make sure that the refrigeration temperature of medicines is stable and controlled. The cold chainindicators include temperature sensors and are designed to control and verify the good state of conservation of the products. In other words, its function is to ensure that the temperature of refrigerated medicines has been maintained.

This way, they guarantee suppliers that the temperature to preserve the medicines has been perfectly maintained and thus, the cold chain has been respected. It is also a way of certifying to the final customer, by means of temperature control, that they receive a product of the highest quality.Why is it important to maintain the temperature for medicines?

One of the most delicate stages in maintaining the cold chain is transport, that is, before and after the products leave the warehouses. If medicines are kept outside the recommended temperature, even for a short period, they can be seriously affected, as some medicines can develop pathogenic microorganisms.

Another highly-effective alternative to ensure that the recommended temperature has been met is the use of irreversible temperature indicators or thermometers for medicine refrigerators. These are adhesive thermometers that control the maximum reached temperature by changing colour. They are irreversible, which means that, on reaching a specific temperature, they permanently change colour. Therefore, they can guarantee that the cold chain was respected.

In short, attention must be drawn to the use of thermometers for medicine refrigerators during transport until they reach the recipient. They are real and unchangeable proof that the required cold has been maintained for the correct preservation of medicines that need to be kept at a specific temperature. This will be the only possible way to know whether the products continue to successfully maintain theirproperties, proving useful for the patients who take them.

Transporting medicines and vaccines Best seller

Adhesive reversible thermometer for refrigerators. This indicator comes with 12 temperature points indicating the temperature of the refrigerator or cold storage by a colour change.

LCD fridge thermometer with 12 levels...29,88 €LCD reversible adhesive temperature indicator. This label changes colour on the basis of the temperature.

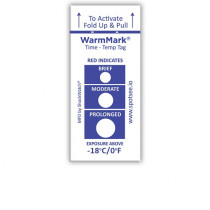

Reversible temperature indicator for the...42,95 €Irreversible time and temperature indicator by color change. This adhesive label alerts you to inappropriate temperature exposure by progressively changing the color of the control points. Each point is calibrated for a specific period of time, thus allowing control of the exposure time at that temperature.

WarmMark Time and Temperature (pack 100...227,50 €The FCP descending temperature indicator is an adhesive label, which, through a color change, alerts us that the temperature has dropped below a critical value. The color change is permanent and irreversible, so it acts as a control signal, recording the event. Supplied in packs of 10 units.

FCP Descending Temperature Indicator (pack...184,17 €The FCP descending temperature indicator is an adhesive label, which, through a color change, alerts us that the temperature has dropped below a critical value. The color change is permanent and irreversible, so it acts as a control signal, recording the event. Supplied in packs of 10 units.

FCP Descending Temperature Indicator (pack...307,00 €

Air transport of medicines

The transport of medicines at controlled temperatures requires the use of transport means with a cold chamber to prevent the cold chain of the medicines from being broken. In general, the temperature should always be kept between 2 °C and 8 °C. It is also essential to use a clean cold room, and carefully load the products to prevent breakage or similar accidents. That being said, controlling the cold chain is fundamental. This can be done using devices like temperature recorders or using simpler solutions, like adhesive indicators, which alert you by changing colour if there is a fault in the refrigeration, both due to excess or lack of cold.

What happens if a vaccine’s cold chain breaks?

The cold chain of thermolabile medicines must be maintained constantly to avoid altering their properties. If this happens, it increases the chance of biological contamination, and they become a serious health threat since their toxicity levels rise.At first glance, it is impossible to detect whether the cold chain for vaccines has been broken. This makes it essential to have a temperature indicator that can warn us if the required thermal conditions were altered along the journey.

Characteristics of proper transport of vaccines

For the transport of vaccines, we must also have vehicles with cold chambers, isothermal boxes, portable refrigerators, ice packs and, most of all, temperature control systems that ensure the preservation of the drugs’ cold chain.

When the cargo arrives at its destination, it must be placed in a vaccine refrigerator that is at the same temperature. The cold chain for vaccine preservation ensures the thermal stability of vaccines, thus minimizing the possibility of germ propagation or drug deterioration, which could create a health problem for the patient.

As we can see, professionals in the sector do not transport all medicines as if they were a single commodity. Following a strict protocol, they follow the laboratory’s instructions at all times to use the most appropriate transport. The temperature range is from 0 °C for vaccines to 25 °C for other commonly-used drugs that do not require refrigeration but do require temperature control.

In these tasks, using irreversible temperature indicators allows unassisted control during transport. By permanently changing colour, they will alert you if the cold chain was broken at any point.

Traditional adhesive thermometers are also useful to check the temperature of the vaccine refrigerator and to prevent inadequate cooling in good time.

We believe we have covered the most important aspects of the transport of refrigerated medicines, thus helping you understand the importance of finding a carrier that strictly complies with the protocols, and uses a suitable temperature control method to ensure the proper preservation, as well as the durability and usability of each medicine.