No products

Prices do not include tax.

Sterilization of surgical material: methods

The sterilization of surgical material is one of the essential tasks in any clinic or hospital. The health of each patient will depend on its correct implementation.

For this reason, we have decided to explain the fundamental terms for their implementation, and to provide a thorough description of the different sterilization methods used in microbiology laboratories, and laboratories in general.

In several of these methods, temperature plays a major role. Ensuring that certain temperatures are reached is essential to guarantee proper sterilization. This is why control methods, such as temperature indicator labels, ensure the result in a comfortable, affordable way.

Main products for the sterilization of laboratory equipment

The TDI adhesive temperature label is an indicator coming with three irreversible temperature points. It has been specifically manufactured to control the sanitizing of industrial dishwashers.

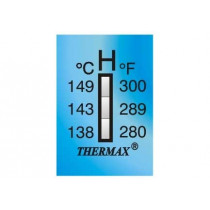

TDI Label- TDI Thermometer for the control...292,88 €Irreversible-type temperature indicator. These temperature labels are adhesive and can be stuck on any surface or product. They change to permanent colour when reaching the marked temperature.

1-temperature irreversible thermometer...25,61 €This product is supplied in packets with 10 thermometers. Irreversible-type temperature indicator with 8 temperature points. This is an adhesive thermometer than can be stuck on any surface or product. The points are marked with temperature in ºC and ºF.

8-level irreversible thermometers (pack 10...15,20 €Adhesive indicator with three temperature points. Supplied in packets with 10 units.

3-level irreversible thermometer (pack 10...9,48 €

Sterilization of surgical material

Here we have three options: dry heat, autoclave and chemicals. As we will see below, however, only two of them are the most used nowadays.

Dry heat

It is carried out using Poupinel ovens, which can heat the instruments to 180 °C.The downside is that you have to wait for them to cool down before using them and that such a high temperature causes them to deteriorate prematurely. It is the least used method.

Autoclave

It consists of two chambers: one external and one internal, in which steam is used to eliminate germs. The most used is the so-called pre-vacuum autoclave. Inside, the oxygen is vacuumed and the steam enters at a temperature of 121-134 °C. Then the vacuum is created once again, and finally, the cooling stage takes place.

Chemicals

Options such as ethylene oxide, formaldehyde, plasma gas and hydrogen peroxide are arranged in chambers for the immersion of the corresponding surgical material.

Sterilization of laboratory equipment

Also, those explained in the following sections must be added to those mentioned above.

Dry heat autoclave

The aim is for the proteins to be denatured, the lipids to melt, and the microorganisms to be dewatered. It is quite a mildly aggressive method for metal instruments. It is suitable for the sterilization of viscous or powdery substances and is effective at a temperature of 120 °C.

Radiation

Radiation is ionizing, given its effectiveness in easily eliminating microorganisms. Gamma radiation is often chosen because of its ability to penetrate. It is very effective in removing germs from Petri dishes.

Sterilization methods used in microbiology laboratories

Two broad groups can be distinguished, including some of the options already outlined.

Chemicals

Alcohols (isopropyl and ethanols), aldehydes (glutaraldehyde and formaldehyde), phenols (xylenol and carbolic acid), ethylene oxide and hydrogen peroxide are mainly used.

Physical methods

Autoclave, dry heat, hot air, incineration, tyndallization, pasteurization, boiling and steam, among others.

We hope that we have given you the necessary facts to know how the sterilization of surgical material and laboratory material works.