No products

Prices do not include tax.

Temperature control in the manufacturing process of beverage cans

The manufacturing process of beverage cans requires thermal control to check the welding spots. All the parts must be welded properly to perfectly preserve the product the can will contain. To ensure maximum watertightness, the batches of cans enter a flame inline furnace that will progressively raise the temperature to 250 °C.

By marking one or more of the cans with heat-sensitive labels before they enter the inline furnace, we will be able to check the temperature reached during the process easily. When the cans come out of the furnace, the labels indicate the maximum temperature the cans were subjected to.

Main thermometers for food can manufacturing

This product is supplied in packets with 10 thermometers. Irreversible-type temperature indicator with 8 temperature points. This is an adhesive thermometer than can be stuck on any surface or product. The points are marked with temperature in ºC and ºF.

8-level irreversible thermometers (pack 10...15,20 €Irreversible-type temperature indicator. These temperature labels are adhesive and can be stuck on any surface or product. They change to permanent colour when reaching the marked temperature.

1-temperature irreversible thermometer...25,61 €Adhesive temperature labels with 6 control points are supplied in packets with 10 units.

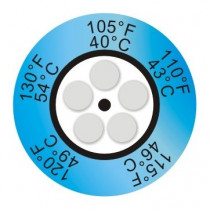

6-level mini irreversible thermometer...13,96 €Circular-type irreversible temperature label. Supplied in packets with 10 units.

Clock-type irreversible thermometer with 5...15,93 €

Quality control in the manufacture of aluminium cans

Quality control in the manufacture of food cans is an essential requirement for health reasons. In the manufacturing processes of any elements or accessories related to consumer products or items that come into contact with living beings, making sure that they comply with current regulations is necessary. Health requirements, HACCP protocols, etc. have been revised and perfected in recent times to prevent the development of viruses and bacteria due to undesirable contamination in packaged products.

A food can that has deteriorated or been damaged by faulty welding can be particularly dangerous for consumption. The germs that develop inside it could pose a threat to living beings and even be fatal.

The improvement of these containers – besides the use of new lighter metals, stainless metals like aluminium, and less rigid and alterable like brass – is largely due to better quality control.

Self-adhesive temperature labels have contributed to a much more reliable and accurate temperature reading. They are a more cost-effective solution than other sensorsAdvantages of using heat-sensitive labels in the manufacture of food cans

- These labels allow for unassisted temperature control since they enter the production line adhered to a can and do not need supervision until the end. Since these labels are irreversible and permanently change colour, it is at the end when we can see the result.

- Because these labels are placed directly onto the product and thanks to their high measurement accuracy, the readings are 100% reliable.

- They are made of self-adhesive paper, which makes them flexible so they can adhere to curved items.

- They are a low-cost sensor compared to other temperature indicators.

- They do not require batteries. Therefore, they do not interfere with electronics or electrical panels involved in the manufacturing process of beverage cans.