No products

Prices do not include tax.

Food preservation methods and temperatures

Food preservation methods seek both to stop the propagation of germs using cold, and to eliminate them through heating processes like sterilization or pasteurization.

These processes can be divided into two large groups according to whether they use heat or cold. Each of them applies to different foods, always aiming to maintain their organoleptic properties as unaltered as possible.

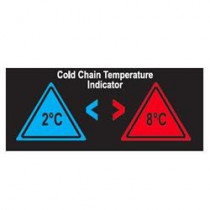

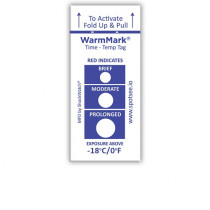

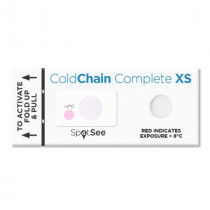

These preservation techniques must apply along the production chain – especially for food preserved with cold. As always, the food preservation temperature must be respected to prevent breaking the cold chain. In heating processes, on the other hand, ensuring that the necessary temperatures are reached is essential to complete the process. In both cases, the use of temperature indicators is indispensable to guarantee the correct result.

The best temperature indicators for food preservation

This product is supplied in packets with 10 thermometers. Irreversible-type temperature indicator with 8 temperature points. This is an adhesive thermometer than can be stuck on any surface or product. The points are marked with temperature in ºC and ºF.

8-level irreversible thermometers (pack 10...15,20 €LCD reversible adhesive temperature indicator. This label changes colour on the basis of the temperature.

Reversible temperature indicator for the...42,95 €Irreversible time and temperature indicator by color change. This adhesive label alerts you to inappropriate temperature exposure by progressively changing the color of the control points. Each point is calibrated for a specific period of time, thus allowing control of the exposure time at that temperature.

WarmMark Time and Temperature (pack 100...227,50 €The FREEZESAFE temperature drop indicator is an adhesive label that, by means of a color change, alerts us that the temperature has dropped below a critical value. The color change is permanent and irreversible, so it acts as a control indicator, recording the event. It is supplied in packs of 100 units.

FREEZESAFE temperature drop indicator...184,17 €Coldchain complete XS is a temperature label for cold chain control. This indicator is irreversible and alerts us by means of a color change if a product has been exposed outside the required temperature range, both above and below it. It is supplied in packs of 100 units.

Coldchain Complete XS cold chain...307,00 €

Refrigeration techniques and temperatures

These techniques are preferably used to preserve vegetables, fruit, fish, meat and seafood. When these are to be marketed fresh, there is no other possibility than to delay their deterioration using cold. To do so, they are subjected to temperatures that are close to and below zero degrees. These are the main methods.Freezing food

This procedure is the one that guarantees a more extended preservation period. However, in some cases, the product may lose its properties. In the process of freezing food, temperatures range from below 0 °C and to −18 °C. This ensures that the enzymes that break down the food slow down or halt their activity, killing the vast majority of the microorganisms.

However, this preservation method requires transport and storage facilities that are equipped to provide suitable temperature conditions. Having a reliable solution for temperature control is also important to guarantee that the food cold chain has not been broken at any time and ensure the food’s preservation.Refrigerated food

Refrigerated food is that which is kept at a temperature above 0 °C, but below 7 °C. The aim is to preserve the products’ freshness, which is achieved by slowing down the activity of the agents that break them down. The storage period of refrigerated food is shorter than that of frozen food. However, refrigeration allows a higher degree of product freshness. Again, controlling the refrigeration temperature of the food is necessary for proper preservation. Adhesive thermometer labels are a perfect solution since they are easily visible.Food preservation through heat

Heat is a powerful weapon to preserve packaged foods. When it comes to milk or preserves, high temperatures are used to eliminate microorganisms, some as dangerous as the Clostridium botulinum bacteria. The most commonly used techniques are the following.Sterilization

This technique is used for packaged food, which is subjected to temperatures of more than 115 °C. Microorganisms, spores and germs are eliminated without a trace, although it does affect the food’s properties. Ensuring that the sterilization temperature is reached through a reliable control method is essential to ensure food safety before the food storage process.Pasteurization

In pasteurization, high temperatures of around 80 °C are applied to inactivate the germs that are present in food. However, the existing spores are not eliminated. This is why the products need to be consumed within around three days and stored in the fridge to be kept cool. This method, nonetheless, does not affect the properties of the food.In short, these are the main commonly-used food preservation methods. In all of them, controlling food preservation temperatures is essential to guarantee the storage period, as well as the chance of transporting them over long distances and enjoying them without unaltering their properties.